Mine Air Heating

Glass fibre reinforced plastic (GRP)

air to air heat exchanger.

A better solution

Mine Air Heating

We are specialised in manufacturing air to air/ plate heat exchangers units. Our units are made of fibreglassreinforced polyester (GRP). Our products have a high resistance on moist, polluted and corrosive air environments with no CO2 emission.

We provide heating and cooling*.

.

Find out more about the advantages

Why us?

- Corrosion resistant composite plates

- Dust and particle resistance due to plates gap

- Self-cleaning heat exchanger

- Low pressure drop through the heat exchanger, only 150Pa

- Pollution: CO2-emissions reduction greater than 95%

- Economy: a pay-back investment

- Independency: +30 years lifetime

- Products are custom made and designe

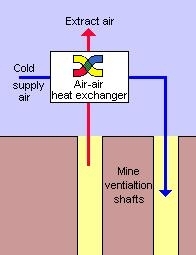

Mine air pre-heating system

Product

The ventilation exhaust air from the mines is both warm and humid and therefore full of heat energy. Normally this energy-rich air is just sent to atmosphere and wasted.

Our air-to-air crossflow plate heat exchanger is a cost-effective method of recovering heat from this exhaust air and pre-heating the fresh ventilation air to the mine shaft.

Millions of BTUs per hour of heat is continuously transferring from the exhaust air to the cold inlet air, saving large amounts of gas otherwise needed by combustion heater units.

Our system heats the inlet air whenever needed whereas gas burners are only used as a top-up heating on the coldest days when there isn’t sufficient heat in the exhaust air.

Our products are always custom made and specifically designed for each application/ customer.

- Heat exchange with a very low freezing point

- A gap within the plates makes it resistent to heavy dusted environments

- Made of Glassfiber-reinforced polymer (GRP)

- Resistent to acids

- Self cleaning due to the condensation on the exchanger

How do it works

Technology

Our air to air (gas to gas) plastic plate heat exchanger are designed for air and gas flows from 50 m3⁄s and up to more than 250 m3⁄s (>600,000 cfm). The design is modular to fit any air and gas flow volume.

The heat exchanger plates are made of glassfibre reinforced polyester (GPR), which makes the whole heat exchanger corrosion proof in corrosive air environment.

Where other non corrosion proof materials like aluminium or steel corrode to destruction within a couple of years, our plastic plate heat exchanger lasts for at least 50 years giving a very favourable return on the investment in the air heat recovery equipment.

A gap between the heat conductive plates enable handling of dusty air and particles with getting blocked.

The maximum temperature of the air or gas into the heat exchanger is 160°C.

The maximum permitted pressure difference between supply and extract side of the heat exchanger is 10000 Pa.

The pressure drop through the heat exchanger is very low, at only 150 – 300 Pa, requiring less fan power than most other heat exchangers.

Heat exchanger position

A great solution for new and existing mines

A better solution

Numbers matters

Our air-to-air crossflow plate heat exchanger is a cost-effective method of recovering heat from this exhaust air and pre-heating the fresh ventilation air to the mine shaft. Better for the environment and cost saving.

*On mines that uses propane

unique technology

Air-to-air principle

An air-to-air heat exchanger brings two air streams of different temperatures into thermal contact, transferring heat from the exhausting inside air to incoming outside airduring the heating season.

Our industrial air-to-air heat exchangers made of glass fibre reinforced plastic (GRP), is a cost effective plate heat exchanger unit with ever improving payback time as energy prices increase, combined with very long economic life.

We have developed the technology of heat recovery from polluted and corrosive emission as well as heat recovery from low temperature process air and gas, an area which has been ignored up until now.

quality and professionalism

Our clients

Zinkgruvan Mining, Sweden

we can do it

Get in touch

Mine Air Heater is design and delivered by Gupex AS, an international engineering company with more than 30 years experience.

Our “building block system”, allows us to deliver all over the globe.

Contact us

- +47 901 53 146 / +47 982 02 927

- info@gupex.com

- Brynsveien 5, 0667, Oslo, Norway